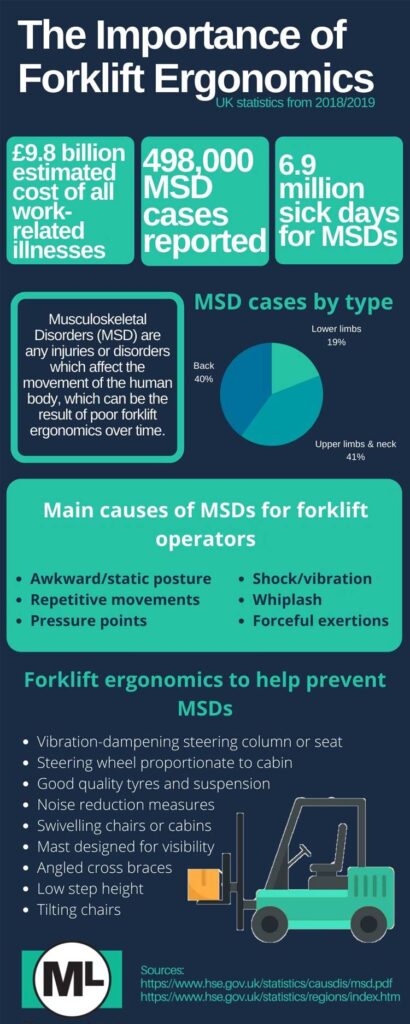

WHAT ARE THE MAIN CAUSES OF ILL HEALTH FOR FORKLIFT OPERATORS?

There are multiple factors to take into account to ensure safe forklift operation. Forklift drivers spend much of their working day sitting and twisting their upper bodies and these repetitive, unnatural postures can lead to serious strain. This strain, particularly on the lower back is amplified by shock and whole body vibration (WBV) through the seat, the steering wheel and the floor panel of the forklift. To counter, WBV Mitsubishi forklift trucks utilise some of the best ergonomic technology to ensure optimum comfort and safety for operators.

The operators can pose a danger to their own health if they aren’t properly trained for the specific forklift they are using. Forklift drivers should take regular breaks to stretch their muscles out of uncomfortable positions and to avoid fatigue.

The Ovako Working Posture Analysis System (OWAS) is used for determining the risk level of harm caused by working postures. Effective forklift ergonomics can reduce the likelihood or at least the severity of work-related ill health.

HOW TO PREVENT INJURIES AND ILLNESS IN THE WAREHOUSE

There are a variety of preventative methods and practices which an employer can put in place to ensure the safest possible environment for their workers. If the following measures are implemented not only will staff be safer but they will also be more productive.

The ergonomics of material handling equipment should be considered before purchase/use. They should provide lumbar support, easy accessibility, high visibility, easy to reach controls, vibration dampening and noise reduction – all of which will reduce the possibility of injury significantly.

Employers should:

- Ensure all staff are appropriately trained on the specific machines in use

- Ensure all floor hazards are known to operators and are dealt with swiftly and efficiently

- Ensure control measures are in place: levelling of surfaces, speed limits and ramps

- Ensure optimum visibility in the facility with the use of mirrors

- Ensure vehicle maintenance and servicing is completed regularly

Forklift Operators should:

- Take regular breaks and remember to stretch muscles throughout the day

- Ensure their back is supported and pedals are within easy reach

- Avoid straining for visibility where possible

- Wear the correct PPE: gloves, high-vis, etc.

According to a scientific study by the University of Žilina, improvement of ergonomic conditions is a factor that can be primarily influenced by the Forklift Manufacturer and secondly by the right type of forklift for the task required. At Multy Lift, we can help you to choose the right forklift for your business needs.

MITSUBISHI ERGONOMIC FORKLIFTS

Mitsubishi are at the forefront of ergonomic forklift design, their forklifts are intuitive and comfortable to use for extended periods of time.

The GRENDiA and TREXiA diesel and LP Gas forklift models are crafted with the operator in mind, both have a wide range of features to ensure comfort during operation. These features include the following:

- All-round visibility: achieved through fitted LED lights, low counterweight design for high visibility whilst reversing, clear-view narrow masts and slim lift cylinders which keep forks and load in view without strain.

- Intuitive steering: fully hydrostatic and angle-sensitive steering for effortless precision, adjustable steering columns with position memory functions to create generous leg room, intuitive fingertip controls, large and easy to reach cowl-mounted hydraulic levers, back up handles and horn buttons for reversing comfortably and fully adjustable armrests

- Brakes and pedals: vacuum-boosted automotive-style pedals at the optimum angle to avoid leg strain, fully hydrostatic drum brakes for excellent control with minimal effort, electronically controlled parking brakes for safe braking without restricting knee and leg movement, precise torque converters and compact turbochargers for controlled acceleration

- Seat: fully adjustable, full suspension cloth or vinyl seats with hip restraints and complete lumbar support for a relaxed driving position

- Noise reduction: rubber-mounted components, fully insulated steel engine hoods, helical gears, enclosed wheel arches, low noise vibration from fully floating powertrains and a noise level of just 78 dBA

- Other features: heaters and air conditioners and wide steps with grab handles

The EDiA electric forklift range excels in efficient ergonomics. These forklifts are renowned for their driveability and intuitive design with smooth, instinctive controls and angled counterweighting. The EDiA range has a choice of models offering distinct benefits so that you can choose the best forklift for your business.

Multy Lift stock a wide selection of highly ergonomic forklifts from renowned manufacturers such as Mitsubishi, Aisle Master and Combilift to ensure your workers are safe and comfortable at work. Call us today on 01623 794 094 to discuss your forklift requirements.